Health & Safety: Eliminating the Risks of Overpressure of Chemical Dosing Systems

An important Health & Safety issue of chemical dosing systems is the risk of overpressure that can lead to incidents in some cases. This is the reason why it is inevitable to understand what are the causes and consequences, and above all, how to eliminate the risks.

Testimonial of an Incident Caused by the Overpressure of a System

Mélanie Cardin, Jr. Eng. – Technical Advisor, Water & Energy

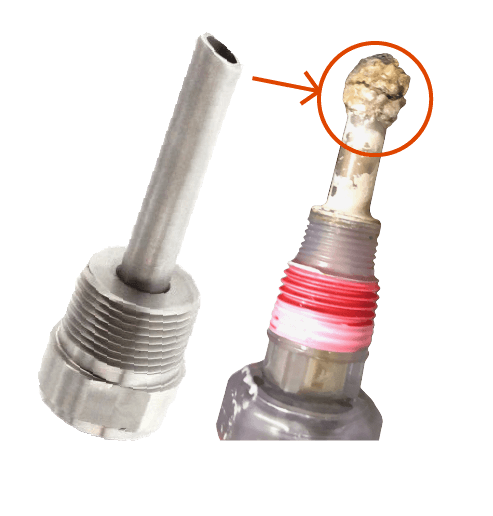

“Working with chemical products under pressure can be extremely hazardous. I experienced this first-hand during start-up of a chlorine and bromine based oxidant dosing system for treating cooling tower water. I got sprayed by a chemical product when a flexible pipe in the system gave way because of too much pressure. In this case, the excess pressure was the result of a blockage caused by chemical crystals.

I am now extremely aware of these issues and, as an engineer, I consider the use of an adjustable pressure relief valve to be an essential part of any chemical dosing system.“

Potential Causes of Overpressure

A series of factors can lead to excess pressure build-up in a chemical dosing system, even in systems operating under very low pressure:

- Blocked pipe

- Blocked injection quill

- Closed isolation valve

- etc.

How to Avoid an Excess Pressure Build-up

A pressure relief device is essential for any dosing system to control the maximum pressure that can be reached in the system.

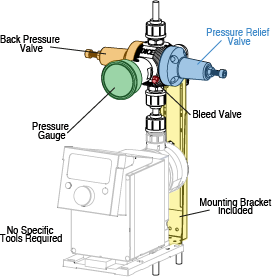

The DICE™ ES offers a simple yet complete solution to Health & Safety issues while optimizing dosing system reliability.

- Adjustable pressure relief valve, to help limit the maximum pressure that can be reached within the system

- Pressure gauge, which makes it possible to validate the proper functioning of the dosing pump and depressurization in case of maintenance

- Bleed valve allows for an easy pump priming and system depressurization in case of maintenance or shutdown

- Adjustable back pressure valve, which helps:

- Maintain constant pressure on the pump, leading to better precision and reliability

- Eliminate siphonage conditions

- Serve as a check valve

Is there a safety feature in your chemical dosing system?

If it’s not the case, contact us to see how we can help you.