DICE™: The Chemical Dosing System

Innovative Chemical Dosing System. All-in-one solution. Simple, Intuitive and Reliable.

Big news!

We’re excited to announce the launch of Shop Meunier Technologies—an online platform simplifying the selection of our DICE products. Distributors, integrators, and users can now access our full product range, list prices, and request quotes.

In its initial phase, the first version is available in English, with prices displayed in USD.

Your feedback is invaluable to us, and we invite you to explore the platform and share your thoughts as we strive to enhance the user experience.

Best,

Meunier Technologies’s Team

Trusted by

Benefits

Addressed Chemical Leaks Challenges

No threaded or glued connections to minimize leakage potential, which reduces downtime and the costs of:

- Operation

- Replacements

- Repairs

- Damages to the facility

2X Reduced Footprint

Simplified and compact system that allows you to reduce consirably the footprint and simplify the operation of the system:

- Minimal fluid volume to ease system

pressurization - Troubleshooting within seconds

- Vertical configuration to avoid gas lock condition

Eased Purchase & Installation

Standard design you can fit anywhere with easy installation:

- No tools nor expertise required for the installation

- Reduced time of installation

- Fully assembled dosing system shipped in 2 weeks*

*Depending on quantities, size and material on hand, on all currently stocked pieces of DICE™ systems.

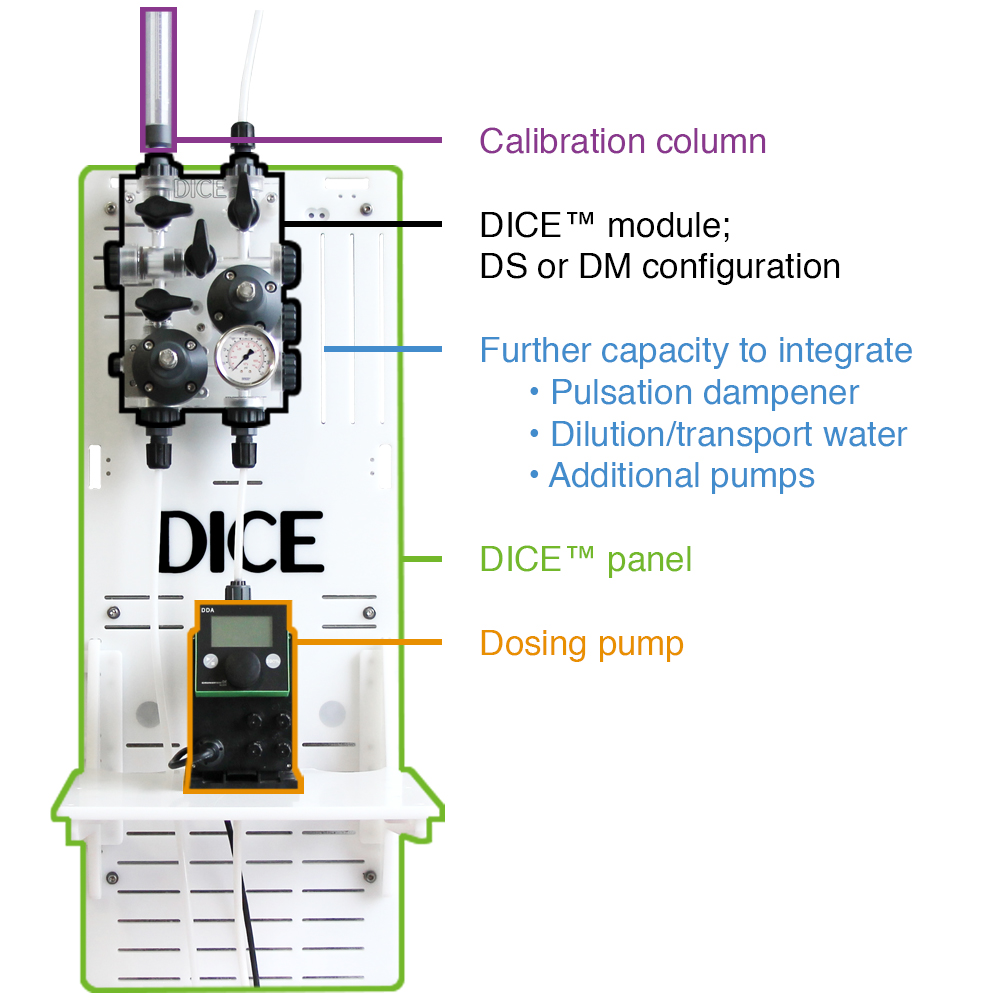

Included in a DICE™ Chemical Metering System

Calibration Column

DICE™ Module

DICE™ Panel

Dosing Pump

Calibration Column

The calibration allows for two things:

- Initial & periodic calibration of your metering pump;

- Visual validation of the actual chemical volume added to the process (an essential troubleshooting feature).

The calibration cylinder comes in various shapes and forms and can be easily selected based on your flow and chemical compatibility.

DICE™ Module

The DICE™ dosing module integrates all the necessary discharge components required to allow for system safety, precision, reliability while having maintenance and troubleshooting capabilities. It comprises a back pressure/non return valve/anti siphon valve, a pressure relief valve, a pressure indicator with isolator, a bleed valve and the required ball valve to perform calibration, maintenance and troubleshooting.

The DICE™ module is available, with different configuration, sizes and materials to cover all your application needs.

DICE™ Panel

The DICE™ Panel is Meunier Technologies solution to offer a compact and versatile wall mount support to assemble your chemical dosing system.

It allows for:

- Simplex, duplex and triplex pumps configuration;

- Top or side mounted calibration column;

- Pulsation dampener integration and support;

- Suction manifold assembly and support;

- Etc.

The panel is available with the option of a spill contentment shelf and fully enclosed configuration.

For larger systems, custom DICE™ wall mount or self support panels can be supplied.

Dosing Pump

The dosing pump is the motorized element which generates the chemical flow in the chemical feed system. Multiple pump technologies are used to dose chemicals in processes such as: diaphragm pumps, peristaltic pumps, progressive cavity pumps, gear pumps, vane pumps, etc.

The DICE™ dosing module is compatible and a key complementary complement to all them.

Available as a complete pre-plumed and tested package or as individual boxed components to be assembled directly on site in a few simple quick steps.

Traditional System VS DICE™ Innovation

Testimonials

“DICE™ provided us with a modular approach for designing and implementing reliable and safe chemical dosing packages, while minimizing the footprint and maximizing the usability of our systems. DICE™ allowed us to remove the complicated piping around the pumps and provided an easy to use and robust module for dosing harsh chemicals. The information was readily available to us by Meunier Technologies and I could not be happier with their team and their partners’ support throughout the entire project. My client now has the most modern, reliable and safe solution for their chemical dosing needs.”