Suction Lift vs Flooded Suction

Comparison between the DICE™ DS and the DICE™ DM

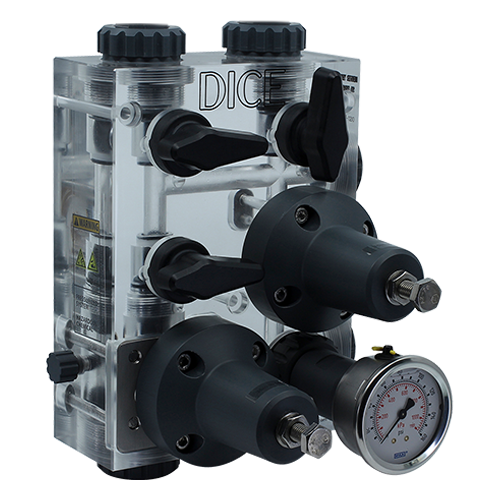

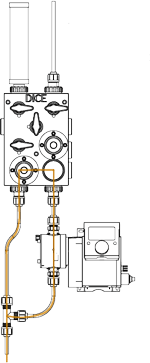

The DICE™ chemical dosing modules are available in two models with the calibration capability. We are talking about the DICE™ DS and the DICE™ DM.

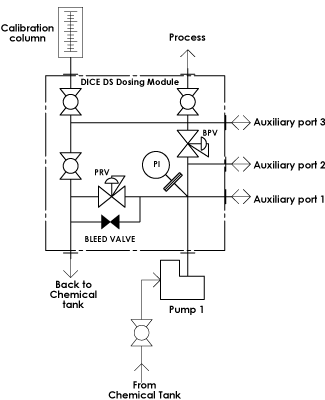

They both have the same components: a back pressure valve, a pressure relief valve, a pressure gauge with an isolator, a bleed valve and three auxiliary ports (for a secondary pump or a pulsation dampener for example). Their normal operation is also the same. The chemical is pumped from the tank, through the DICE™, with the maintained pressured by the back pressure valve, and to the process.

In a few words, the difference between the two dosing modules is that one is designed for suction lift applications and the other for flooded suction application. The difference in the design of the two modules is the addition of a ball valve in the middle of the DICE™ DM module, used for calibration, as detailed below.

Suction Lift

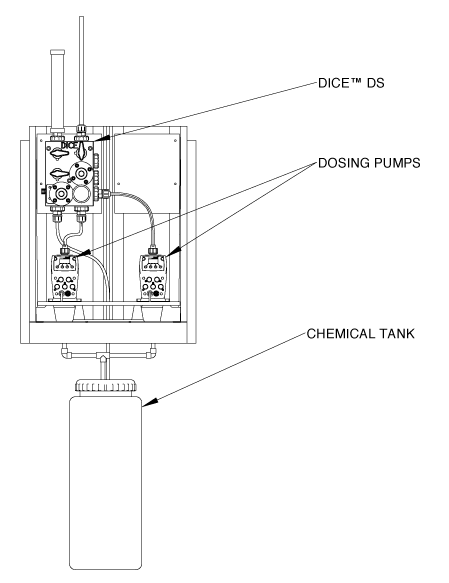

An application with suction lift is defined by a tank fluid level that is lower than the pump inlet. Suction is required to draw fluid from the chemical tank.

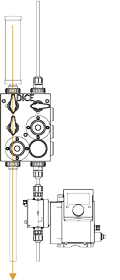

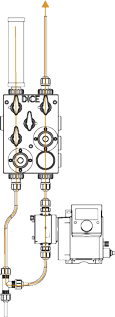

Both DICE™ DS and DM models are suited for suction lift applications.

DICE™ DS

DICE™ DM

Flooded Suction

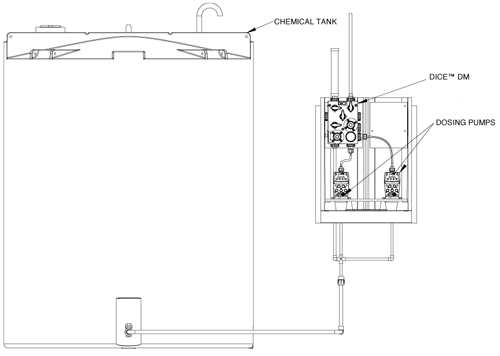

An application with flooded suction is defined by a tank fluid level that is higher than the pump inlet. The pump inlet therefore has constant positive pressure.

Depending on the fluid level inside the tank you could either be in the presence of a flooded suction (example when the tank is full) or a suction lift (example when the tank is near empty).

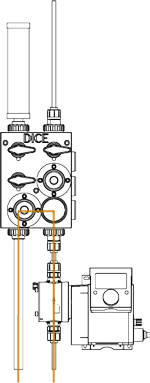

The DICE™ DM is suited for flooded suction applications.

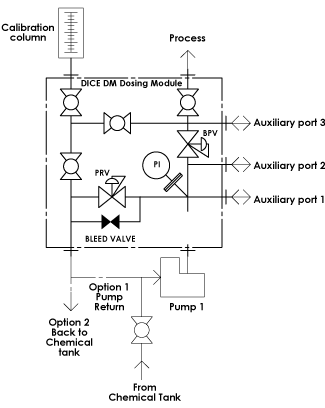

P&ID

DICE™ DS

DICE™ DM

Emptying the Calibration Column

As mentioned, both models can be used to perform a pump calibration. How the calibration column is drained depends on the configuration.

After performing a pump calibration with a suction lift application, the column is emptied and sent back to the chemical tank located under the system, using gravity.

For more details, watch our video on How to Perform a Pump Calibration using a DICE™ DS Module.

Since there’s a positive pressure at the pump suction for flooded suction application, we won’t be able to drain the calibration column content using gravity. The additional ball valve on the DICE™ DM allows the content of the calibration column to be drained with the pump. This configuration also allows doing a drawn down calibration of the pump if required.

The Pressure Relief

In the case of a blocked pipe, a blocked injection quill or simply a closed isolation valve, the pressure relief valve will open. It will cycle back the excess pump fluid to the chemical tank or directly to the pump suction depending on the configuration. This will prevent the system from over pressurizing.

With the DICE™ DS suction lift configuration, the pressure relief valve is routed back directly to the chemical tank.

Therefore, the excess pump fluid is cycled back to the tank.

With the DICE™ DM flooded suction configuration, the pressure relief valve can be routed and looped directly to the pump inlet. This allows the installation to only have one feed line coming from the storage tank.

About the DICE™ Dosing Modules

Learn more about the DICE™ DS and DM features and technical informations.